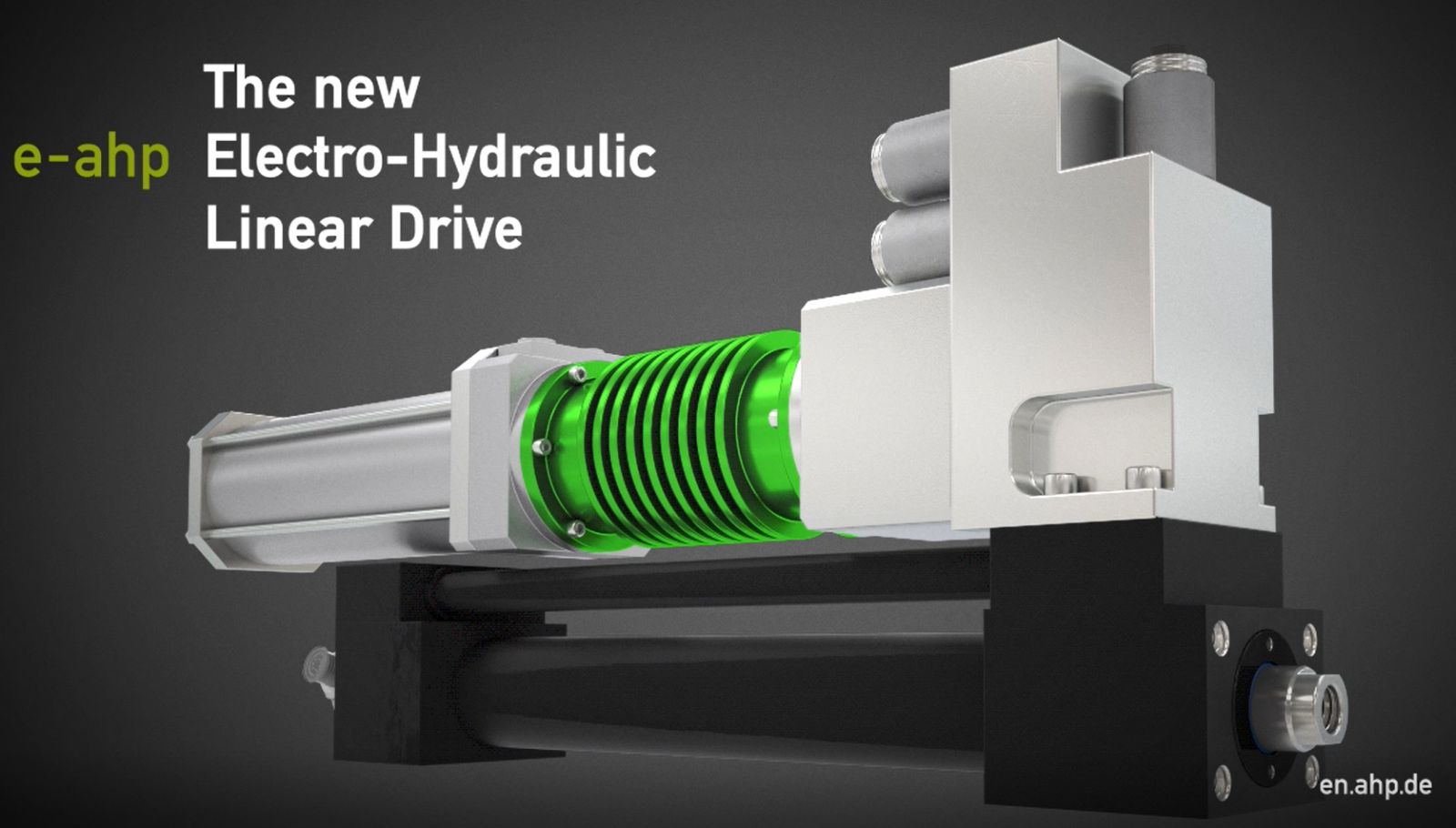

ELECTRO-HYDRAULIC LINEAR DRIVE

NEW AND REVOLUTIONARY

·THE ALTERNATIVE TO SPINDLE DRIVES

being completely insensitive to external force impact, they are virtually wear-free even in continuous operation.

uses energy only when it is actually needed.

Maximum forces

very high forces of up to 625 kN (62.5 tons); with our special actuators, even up to 5 MN (500 tons)

Very dynamic

both for high force build-up and for high travel speed

Precisely controllable

very precise control of force or position, even in the μm range

Easy integration

simplifies initial installation and maintenance through purely electrical integration

· THE ALTERNATIVE TO HYDRAULIC DRIVES

No hydraulic unit

avoids costs and effort for a power unit, hydraulic hoses and piping

Clean and ecological

completely encapsulated and filled ex-factory with a minimum amount of hydraulic oil

Easy integration

simplifies initial installation and maintenance through purely electrical integration

Very energy-efficient

uses energy only when it is actually needed

Very dynamic

both for high force build-up and for high travel speed

Precisely contorllable

very precise control of force or position, even in the μm range

Maximum forces

very high forces of up to 625 kN (62.5 tons); with our special actuators, even up to 5 MN (500 tons)

Robust and wear-resistant

being completely insensitive to external force impact, they are virtually wear-free even in continuous operation.

E-AHP Series

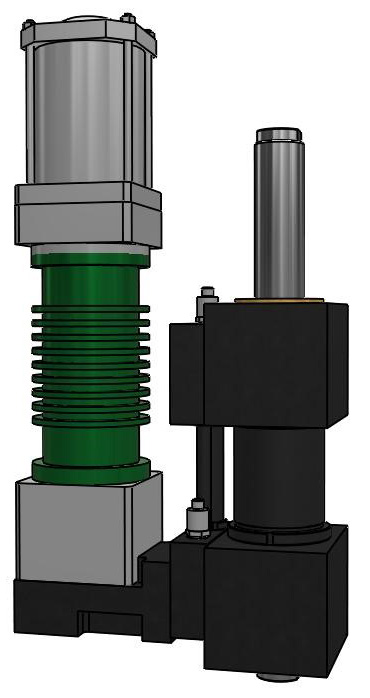

BASIC

The entry point for autarkic hydraulic axes

Autarkic hydraulic axes are compact units consisting of hydraulic cylinder and motor-pump unit. They can be controlled like electromechanical spindle units. The servo motor is controlled by means of a commercially available frequency converter.

Our units support all well-known manufacturers such as Siemens, Beckhoff, KEB, SEW, Schneider,...

Compared to electromechanical axes, the E-AHP units are characterized by very high forces and very low wear. Even if always the same positions are approached, this is no problem with these units.

E-AHP basic units are characterized by their simple design. The retraction and extension speeds and forces are the same due to the so-called synchronous cylinder.

• For punching, bending, cutting, pressing, etc.

• Highly precise positioning (< 5 µm)

• Highly precise pressure and force control

• Full 4-quadrant operation (bi-directional push/pull)

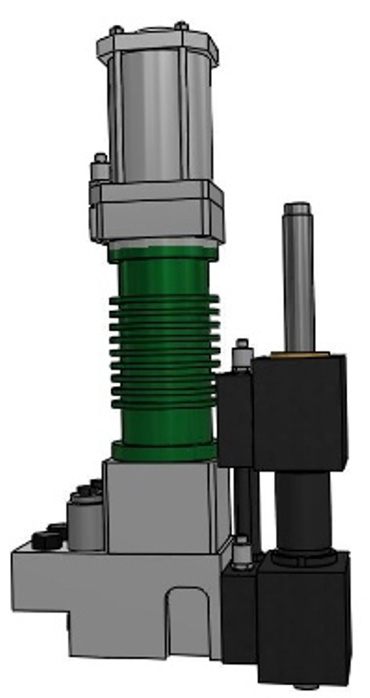

PROVE

Synchronized with additional options

Both units, the E-AHP basic and the E-AHP prove, are based on a synchronous cylinder.

While the basic unit only has a high-quality servo motor, the prove unit has additional valves integrated for load holding or other control tasks.

Shut-off valves and the like can also be integrated in the prove axis and thus a performance level of D/E can be achieved.

• For punching, bending, cutting, pressing, etc.

• Press safety

• Performance Level D/E possible

• Highly precise positioning (< 5 µm)

• Highly precise pressure and force control

• Full 4-quadrant operation (bi-directional push/pull)

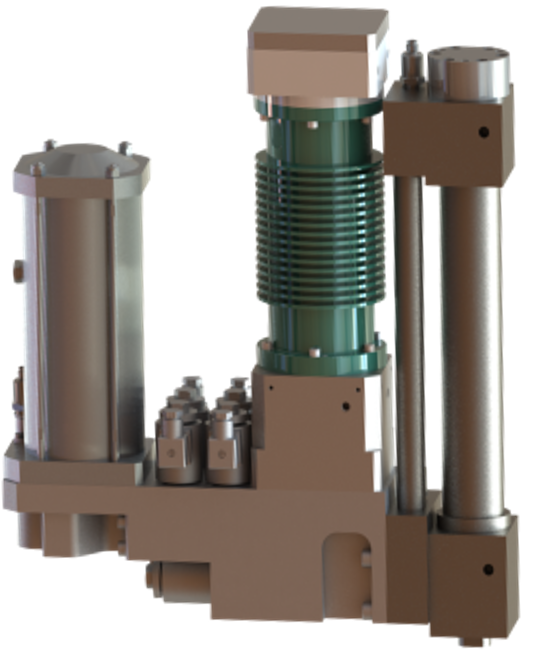

PERFORMANCE

Highest precision - maximum energy efficiency

These units differ from our E-AHP basic and E-AHP prove units in two features:

1.The E-AHP performance is based on a differential cylinder, this allows and a so-called regeneration mode (rapid traverse) and the entry and exit forces are different. This unit can be built the most compact.

2.The E-AHP performance unit is equipped with a valve block as standard, which offers many possibilities. One of these possibilities is to maintain pressures for a very long time without using energy here.

As with the prove unit, various control tasks can be performed here with the integrated valves. A performance level PL D/E is possible.

• For punching, bending, cutting, pressing, etc.

• Press safety

• Performance Level D/E possible

• Highly precise positioning (< 5 µm)

• Highly precise pressure and force control

• Full 4-quadrant operation (bi-directional push/pull)

E-AHP PERFORMANCE – Download Area

中文

中文